About Ocean Sun

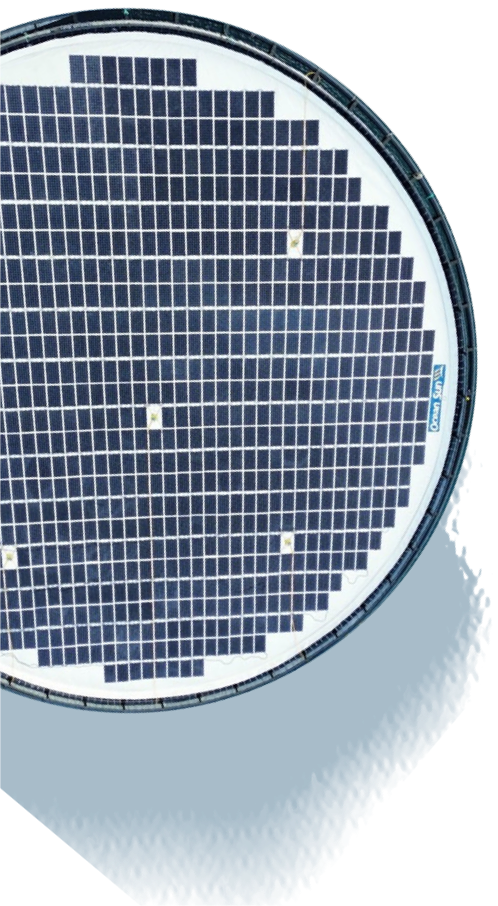

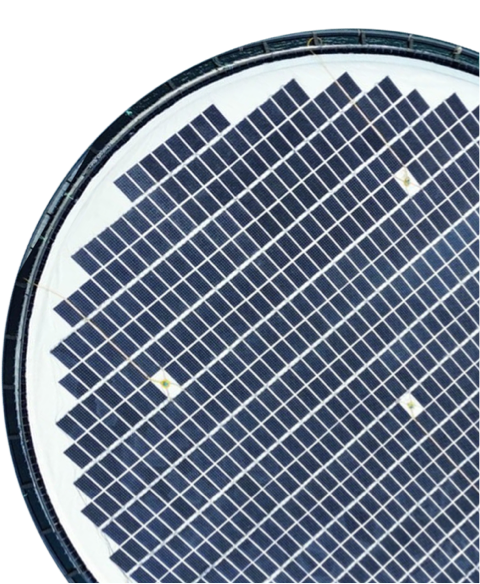

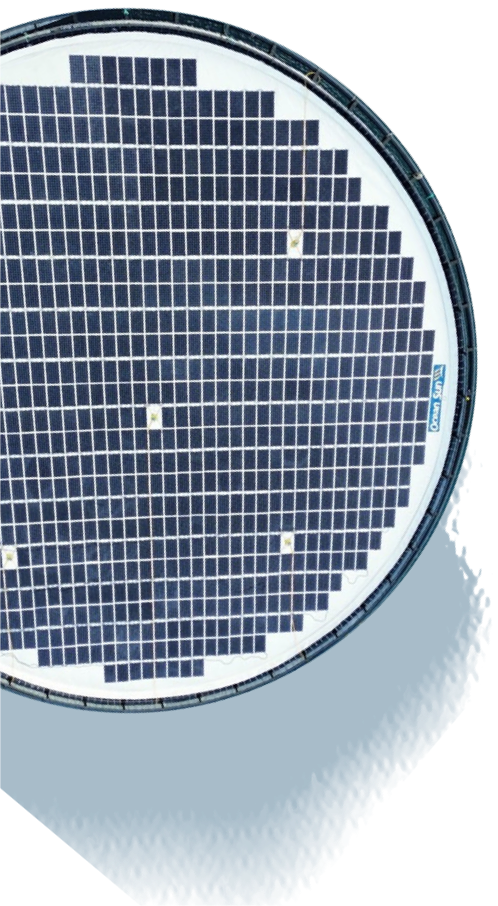

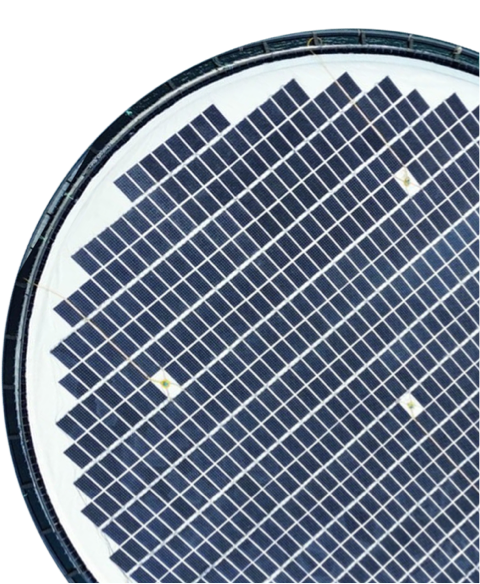

Inspired by Norway’s maritime legacy, Ocean Sun has developed a patented floating solar solution where photovoltaic modules rest directly on a flexible membrane floating on water. This unique approach delivers superior cooling, improved energy yield, and minimal material use.

Tested in harsh marine environments and verified by third parties, our technology enables scalable, low-impact solar power—ideal for reservoirs, coastal sites, and offshore deployment.

LEARN MORE